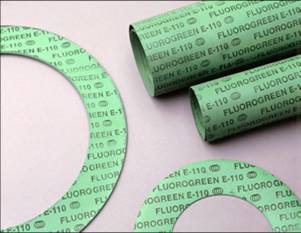

E-110 FluorogreenTM

Fluorogreen E-110 is tested and proven unsurpassed when low deformation material is required. It is a chemically modified material, and uses the same manufacturing process as Fluorogreen E-600, giving the user ultra-low deformation characteristics at temperatures in the range of 500 degrees F.

It is the recommended material for use in sodium hydroxide (black liquor) applications.

Fluorogreen E-110 is an excellent choice for the most critical applications and is a superior replacement to Gylon 3510.

CONTAINS NO ASBESTOS

All UFC Fluorogreen products are made in the U.S.A.

E-110 Fluorogreen is a registered trademark.

|

ASTM Method |

Characteristic |

Fluorogreen E-110 |

|

F-37 |

Sealability |

0.007 |

|

F-38 |

Creep Relaxation % |

6.0 |

|

F-36 |

Compresibility Range % |

3-4 |

|

F-152 |

Tensile Strength, PSI |

2307 |

|

D-638 |

Elongation |

450 |

|

D-792 |

Specific Gravity |

2.02 |

|

D-1700 |

Hardness, Shore D-2 |

61 |

|

F-36 |

Recovery % |

50 |

Physical Properties

Temperature and Pressure Ratings

|

Material |

Pressure |

Temperature |

Color |

|

Fluorogreen E-110 |

1200 PSI |

-350 to +550 F |

Green |