Soot blower carriages need constant monitoring and repair. High temperature steam passing by the gear box and through the lance bearing hub causes lubricant breakdown leading to seal, bearing and gear falure. As a result, there is constant maintenace, seal leakage, equipment replacement, and operating inefficiencies.

UFC Fluorogreen has produced the FluoroPac Soot Blower Packing set using E-900 to protect high temperature machinery against wear in inefficiencies. This gives FluoroPac a decisive advantage in regards to in-service life and the ability to maintain a seal while supporting the insulated feed tube. FluoroPac has no wire reinforcement to wear in the feed tube and will not absorb water. With a modified "V" style configuration FluoroPac Soot Blower Packing is priced competatively and out performs more traditional lines of soot blower packing.

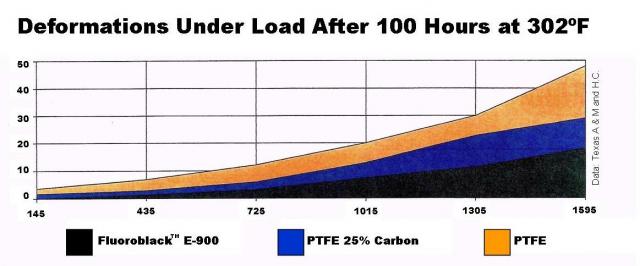

All FluoroPac Soot Blower Packings are compression auto-molded from E-900 Fluoroblack material. Fluoroblack E-900 is chemically modified containing a specially formulated electrocarbon filler material and is an excellent material for prolonged service against high concentrations of hydrofluric acid. This combination of materials may make E-900 Fluoroblack the lowest deforming PTFE based material available.

A major pulp and paper mill in the South has stated, "FluoroPac has outperformed all other packing we've tried. It's lasted in conditions for months when other packing has only lasted days."

|

ASTM Method |

Characteristic |

Fluoroblack E-900 |

|

F-37 |

Sealability |

0.001 |

|

F-38 |

Creep Relaxation % |

17 |

|

F-36 |

Compressability Range % |

5-7 |

|

F-152 |

Tensile Strength, PSI |

2400 |

|

D-638 |

Elongation % |

150 |

|

D-792 |

Specific Gravity |

2.11 |

|

D-1700 |

Hardness, Shore D-2 |

66 |

|

F-36 |

Recovery % |

33 |

Physical Properties

|

Standard Sizes |

|

|

|

2-3/8" X 3-1/8" X 3-3/8" Deep |

|

|

2-3/8" X 3" X 2-3/8" Deep |

|

|

2-3/4" X 3-1/2" X 3-1/4" Deep |

|

Working Width |

|

|

|

Temperatures to 500 F |

|

|

pH: 0-4 |

This is a general guide and should not be the sole means of selecting or rejecting these materials. The above data was independently combined by: Texas Engineering Experiments Station, Materials and Structures Laboratory, Royce E. Wiseenbaker Engineering Research Center, Texas A&M University System, College Station, Texas 77843, 409-854-7328 and other independent sources.

WARNING: The data set forth on this site is typical. The user's specific application should be combined with independent study and evaluation for the materials suitability. For recommendations please contact UFC Fluorogreen. Selecting the wrong sealing products could reult in property damage and/ot personal injury. We assume no responsibility for errors contained on this site.

Temperature & Pressure Ratings

|

Material |

Pressure |

Temperature |

Color |

|

E-900 Fluoroblack |

1400 PSI |

-350 to +500 F |

Black |