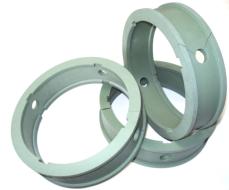

Lantern Ring

It is not always possible to use a standard packing configuration stuffing box to seal the shaft and centrifugal pump. The pump suction may be under a vacuum making outward leakage impossible or the fluid may be too hot to provide adequate cooling of the packing. Under these conditions, a modification to the standard packing of the stuffing box is required, and a Lantern Ring offeres an excellent Solution.

A Fluorogreen Lantern Ring is a superior lantern ring installed near the center of the packing box which is fed cool clean liquid from the pump discharge or from an external source. The Lantern Ring distributes the liquid uniformly around the shaft to provide cooling lubrication. The fluid entering the Lantern Ring cools the shaft and packing, lubricates the packing, and seals the joint between the shaft and packing against air leakage into the pump.

UFC Fluorogreen produces Lantern Rings using all of our engineered PTFE materials. Fluorogreen Materials can be used when low deformation is needed and is particularly suited for use in caustic environments and are tested and proven superior cryogenic materials.

For example, E-600 Fluorogreen is the material of choice for NASA's liquid oxygen and liquid nitrogen and is unequaled in performance in the ever changing, high tech space industry.

|

ASTM Method |

Characteristic |

Fluorogreen E-110 |

Fluorogreen E-600 |

Fluoroblue E-140 |

Fluoromaroon E-250 |

Fluoroblack E-900 |

F-37 |

Sealability |

0.007 |

0.009 |

0.007 |

0.002 |

0.001 |

F-38 |

Creep Relaxation % |

6.0 |

6.0 |

30 |

42 |

17 |

F-36 |

Compressibility Range % |

3-4 |

3-4 |

20-35 |

6-7 |

5-7 |

F-152 |

Tensile Strength, PSI |

2307 |

2660 |

2100 |

4521 |

2400 |

D-638 |

Elongation % |

450 |

300 |

372 |

650 |

150 |

D-792 |

Specific Gravity |

2.02 |

23.0 |

2.10 |

2.16 |

2.11 |

D-1700 |

Hardness, Shore D-2 |

61 |

61 |

57 |

59 |

66 |

F-36 |

Recovery % |

50 |

43 |

30 |

50 |

33 |

Physical Properties

Temperature & Pressure Ratings

This is a general guide and should not be the sole means of selecting or rejecting these materials. The above data was independently combined by: Texas Engineering Experiments Station, Materials and Structures Laboratory, Royce E. Wiseenbaker Engineering Research Center, Texas A&M University System, College Station, Texas 77843, 409-854-7328 and other independent sources.

WARNING: The data set forth on this site is typical. The user's specific application should be combined with independent study and evaluation for the materials suitability. For recommendations please contact UFC Fluorogreen. Selecting the wrong sealing products could reult in property damage and/ot personal injury. We assume no responsibility for errors contained on this site.

Material |

Pressure |

Temperature |

Color |

E-110 Fluorogreen |

1200 PSI |

-350 to +500 F |

Green |

E-600 Fluorogreen |

1200 PSI |

-350 to +500 F |

Green |

E-250 Fluoromaroon |

1200 PSI |

-350 to +500 F |

Maroon |

E-900 Fluoroblack |

1400 PSI |

-350 to +500 F |

Black |

E-140 Fluoroblue |

800 PSI |

-350 to +500 F |

Blue |

E-120 25% Glass Filled |

1000 PSI |

-350 to +500 F |

Off White |