Pressure Sintering vs. Calendaring

With vast amounts of literature available on calendaring, most industries and distributors of sealing materials would find it interesting that many manufacturers use this practice. Calendaring is a finishing process used on materials where it is folded in half and passed under rollers at high temperatures and pressures to produce a finished material. Calendaring has been the sealing industries standard for decades and large producers such as Gylon, Tealon and Novus have flooded the market with material that cannot meet the expectations of their customers. A calendering finish is easily destroyed, and does not last.

For years it was believed this process was an important improvement for the sealing industry since it used less PTFE. The use of less PTFE increased the resistance to creep and also improved the overall hardness of the materials being processed. By controlling the direction of the fibers of materials and by increasing the strength it reduces the cost to the manufacture. It seems as if this is truly a “good deal”. However, this so called “good deal” is for the manufacturers of PTFE alone. For the end-user, it is not such a “good deal”.

As all manufacturers and distributors know, PTFE does not bond to anything but itself. It will bond however if the surface is etched, then the PTFE can be bonded. The actual science of PTFE in short is where the PTFE must go around small fibers and bond to itself. Calendered sheet uses approximately 50%-60% filler. In most cases, silica or glass fibers are used to increase the strength of the material. For example, Bronze filled PTFE is typically 55% filler. The increase in the percentage of filler increases the hardness.

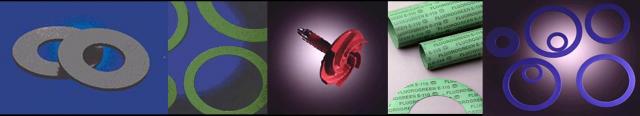

There are manufacturers who produce materials that do not use the calendered process. The process to make a more durable material that leaves no crevices between layers is called pressure sintering. By utilizing this different type of process ensures there are less voids in the materials. These manufacturers who use a pressure sintered PTFE use 20%-25% filler material. By pressure sintering this will compensate for most of the difference in hardness when compared with high-filler sheet.

Filled PTFE sheet is commonly used to stamp or cut gaskets. As we all understand the sealing industry, gaskets are used to prevent leaks at the flanges of pipes. PTFE is a soft polymer that actually makes the seal. The glass or silica fibers that are used as fillers are not making the seal. In fact, the fibers exposed will allow fluids around them. When the pressure and temperatures increase around the seal, the filler material will start compromising the integrity of the seal by taking the gasket apart slowly. Most chemicals will attack the PTFE or the glass so this degradation of the gasket will be a mechanical failure due to the excess of fibers in a hot and pressured environment.

UFC Fluorogreen uses a pressure sintered process and has been found to be one of the highest quality materials on the market. The Fluorogreen family of PTFE sheet materials surpasses most industry standards. By using proprietary pressure-sintering cycles and the use of chemically modified PTFE make the sheet material and machined parts more likely to seal. Our chemically modified PTFE is still 100% PTFE. However, with our pressured sintering process and the highest quality of materials will give the end-user an astounding product. Fluorogreen’s filled sheets are trusted by NASA, Lockheed Martin and the United States Air force to seal cryogenic fuels. Why? Our materials have offered extremely low leak rates due to minimized voids and leak paths due to our process and quality ingredients.

A cheap gasket is the most expensive gasket; the more you have to replace it, the more labor and low production costs are incurred. For quality and customer satisfaction UFC Fluorogreen is the name to remember.

UFC Fluorogreen

The Number One Choice